【合作案例精选】阿姆河数字气田项目

2024-04-172023年5月23日,在“中国-上海合作组织数字技术合作发展论坛”开幕式上,《中国-上合组织国家数字领域合作案例集(2023年)》(以下简称案例集)正式发布。此案例集从申报企业、应用国家、案例简介、应用背景及实施效果等多个角度对入围案例的创新成果和最佳实践进行系统性归纳与梳理。合作案例应用覆盖中国、俄罗斯、印度、哈萨克斯坦、乌兹别克斯坦等国家,有效推动了上海合作组织国家数字领域产品、服务、应用、数字基础设施和解决方案方面经验共享,为上海合作组织国家数字领域国际合作树立了标杆典范。案例集中入选的37个项目颇具代表性,本篇文章将对《阿姆河数字气田项目》案例进行详述。

中国上海合作组织大数据合作中心已开启报名通道,面向国内外公开征集2024年度“中国-上合组织国家数字领域合作案例”,欢迎国内外企业、研究机构、学术机构和高等院校积极申报。

案例介绍

该案例由红有软件与中国石油(土库曼斯坦)阿姆河天然气公司共同完成。案例的主要目标是建立一套涵盖勘探开发领域,包括油气勘探、开发生产、工程建设、经营管理等业务的数据采集、数据传输、数据存储、数据发布、应用研究、协同决策为一体的综合信息管理系统,从而全面提升阿姆河气田数据共享服务能力,极大地推动数据深化应用水平,对有效地促进勘探开发生产管理、地质研究具有十分重要的意义。

案例所属领域

上合之能(数字能源)

案例应用国家

中国、土库曼斯坦

案例背景

为实现信息化与工业化的融合,提高天然气生产管理水平,中国石油阿姆河天然气公司提出了建设“阿姆河数字气田”国家重大示范工程项目,“勘探开发生产管理系统”是其中的一项重点研究课题,具体包含:

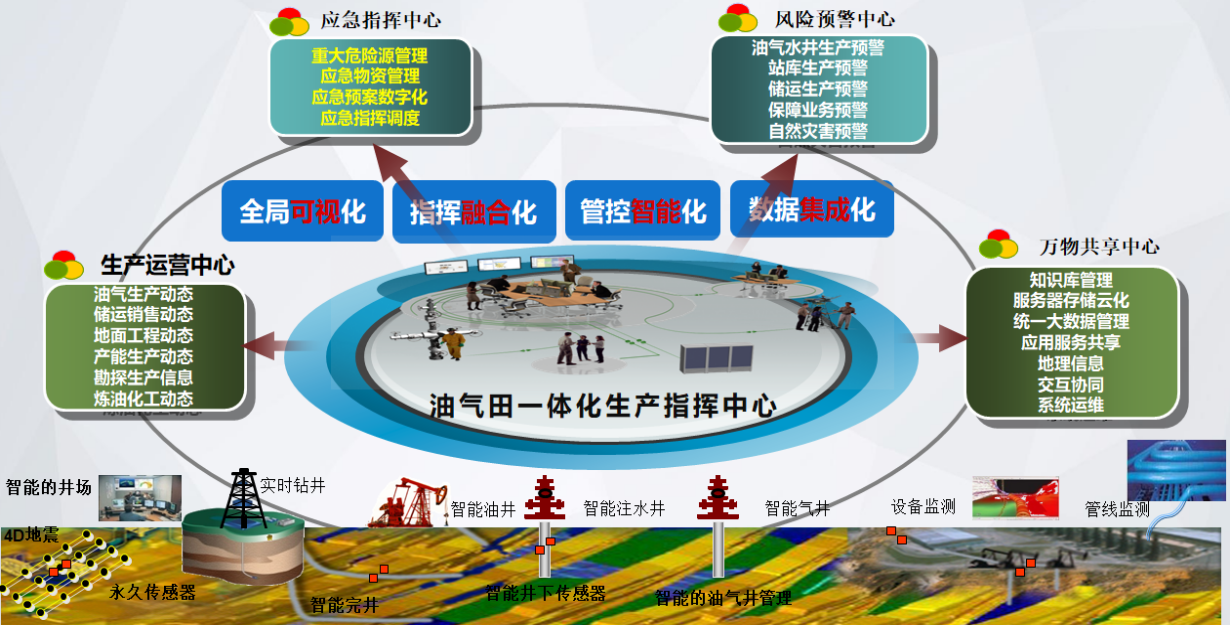

(1) 建立阿姆河气田生产指挥系统,以厂、站指挥平台为节点,上下贯通、左右衔接、互联互通、信息共享、互有侧重、互为支撑、安全畅通的平战双模式指挥体系,支撑阿姆河气田生产业务、生产调度、应急指挥等业务的实施,宏观展示阿姆河气田综合生产运行情况和勘探开发生产态势,包括天然气生产动态、钻井动态、天然气库存、天然气销售、安全生产等信息。构建可视化综合展示平台,供各专业领域人员协同工作。分业务区块展现各自专业领域内容,能够穿透深入查看内容。支持各级业务人员主要的日常个人工作。同时,内容可以方便地切换到大屏幕上。各相关业务人员按需通过移动终端互联互通和移动APP共享应用,实现现场间、现场同后线协同。

(2) 建设阿姆河气田智能采气厂分析体系,针对天然气生产计划制定、跟踪、调整需多业务科室协同配合,实现年度产量生产运行、新井投产、增产措施等计划流程线上化,多部门协同办公实时跟踪计划进展和运行情况,并根据实施情况及时进行调整。同时针对天然气生产的组织实施、生产动态跟踪、产量分析调整的全面线上化流程管理,展示生产运行跟踪过程中各环节的关键指标,实现单井动态异常的实时预警,为生产决策提供依据。并针对生产运行业务在计划管理、运行跟踪过程中产生的关键指标,通过对比分析、趋势分析、同比分析、占比分析等功能,以结果为导向,进行对标管理,为不同岗位人员业务工作提供辅助,并对标结果深度溯源,透视潜在问题和价值,提升管理优化。

案例应用效果

该案例中,采用了四大关键技术实现综合信息管理系统:

(1) 构建以多元数据采集、传输、融合共享为基础、以数据一体化融合应用为核心的数据交换平台,支撑油气勘探、开发生产、工程建设、经营管理等业务,最终实现油田数字化运营、智能化决策及一体化管控;

(2) 构建生产指挥跨专业领域协同的一体化生产优化模式的解决方案。综合数据管理及调度服务建设,融合勘探、开发、生产、钻完井、调度、应急等业务数据,综合服务油田生产调度管理和应急运营;支持油田开发生产综合业务展示、趋势分析、远程会商、应急事件处理、应急保障系统等功能;

(3) 构建油田生产GIS地理信息图形管理,提供快速、灵活、准确的地理位置信息和相关属性资源的空间展示能力;

(4) 围绕着阿姆河气田生产运行数字化闭环管理目标,从操作层、决策层、管理层业务需求出发,归纳抽取符合数字化天然气生产运行管理业务模型、业务活动及业务对象及其之间的关系,力求建成一套标准统一、采集源点唯一、数据处理规则统一的天然气生产一体化运行分析综合管控平台。

通过阿姆河数字气田的建设,满足各业务数据的集成和共享应用,实现天然气生产从生产计划制定、执行、跟踪、评价与优化的生产运行全过程跟踪管理和有效分析,利用全局视角对生产关键指标进行多维展示,解决生产动态数据共享不畅、资源运行调度响应能力弱、辅助决策能力不足问题,实现生产运行的一体化管理,满足生产运行管理、生产动态信息数据共享分析以及有效推动生产协作,为管理、决策层指挥生产经营提供科学依据。

企业介绍

红有软件股份有限公司是扎根于新疆本土的软件和信息服务业企业,在乌鲁木齐、克拉玛依、北京、西安、成都、深圳等地设有研发中心。主营业务涉及智能油田、智慧城市领域的规划设计、产品研发、项目实施以及系统集成、系统运维。智能油田市场涵盖中石油、中海油、中石化、延长集团等国内企业以及阿姆河、阿克纠宾等国外油气田。智慧城市市涵盖自治区政府部门、乌鲁木齐、昌吉、阿克苏、阿勒泰、哈密等地州市。

Case Introduction

This case was jointly completed by Hongyou Software and CNPC (Turkmenistan) Amu Darya Gas Company (CNPCIT). The main goal of this case is to establish a comprehensive information management system covering the field of E&P, including oil & gas exploration, development and production, engineering construction, operation and management, and integrating data collection, data transmission, data storage, data release, application research, and collaborative decision-making, so as to comprehensively improve the Amu Darya gas field's data sharing service capacity, and greatly deepen the data application level, which is of great significance to effectively support the management of E&P production, as well as geological research.

Category

Digital Energy

Country of application

China, Turkmenistan

Case background

In order to realize the integration of information technology and industrialization and improve the level of natural gas production management, CNPCIT proposed the national major demonstration project of the "Amu Darya Digital Gas Field", and the "E&P production management system" is one of the key research topics, which includes:

(1)Establishing the Amu Darya gas field production command system, which is a safe and smooth dual-mode command system featured by interconnectivity, information sharing and mutual support with the plant and station command platforms as nodes. It will support the implementation of the production business, production scheduling, emergency command and other operations in Amu Darya gas field, and macroscopically display the comprehensive production & operation status and the E&P production situation in Amu Darya gas field, including natural gas production dynamics, drilling dynamics, natural gas inventory, natural gas sales and safety production. Constructing a visualized and comprehensive display platform for the collaborative work of personnel in various professional fields. Displaying the contents of each specialized field in business blocks, with the ability to penetrate and view the contents in depth. Supporting the main daily personal work of business personnel at all levels. At the same time, the content can be easily switched to the big screen. All relevant business personnel can realize inter-site and on-site and backline collaboration through mobile terminal interconnection and mobile APP sharing application on demand.

(2)Constructing Amu Darya Gas Field Intelligent Gas Production Plant Analysis System, which, in response to the need for the cooperation of multiple business sections in formulating, tracking and adjusting natural gas production plans, puts the planning process of annual production operation, bringing in new wells, and well stimulation, etc. on line, and enables real-time tracking of the progress and operation of the plans by multiple departmental offices, as well as timely adjustments based on the implementation situation. At the same time, in response to the comprehensive online process management for the organization and implementation of natural gas production, tracking of production dynamics, analysis and adjustment of production, it demonstrates the key indicators of each link in the tracking process of production operation, and realizes real-time early warning of abnormalities in the dynamics of a single well, providing the basis for production decision-making. And for the key indicators generated in the process of plan management and operation tracking for the production & operation business, it carries out results-oriented benchmarking management through comparative analysis, trend analysis, year-on-year analysis, percentage analysis and other functions, provides assistance for the business work of personnel in different positions, and identifies the causes of the benchmarking results, gaining insights into the potential problems and value, and enhancing the optimization of management.

Case application effect

In this case, four key technologies were used to realize an integrated information management system:

(1)A data exchange platform was built based on multivariate data collection, transmission, fusion and sharing, with data integration and fusion application as the core, to support oil & gas exploration, development and production, engineering construction, operation and management, and ultimately realize the digital operation, intelligent decision-making, and integrated management and control of oilfields;

(2)Solutions were developed for an integrated production optimization model for production command cross-disciplinary collaboration. Integrated data management and scheduling services were developed, integrating exploration, development, production, drilling and completion, scheduling, emergency response and other business data to provide integrated services for oilfield production scheduling management and emergency response operations, and support functions such as oilfield development and production integrated business demonstration, trend analysis, remote conferencing, emergency handling and emergency support system;

(3)GIS geographic information graphic management of oilfield production was developed to provide fast, flexible, and accurate spatial display capability of geographic location information and related attribute resources;

(4)To achieve digital closed-loop management of production & operation in Amu Darya gas field, and starting from the business requirements of operation layer, decision-making layer and management layer, efforts were made to summarize and extract the business model, business activities and business objects and the relationship between them in line with the digital natural gas production & operation management, and build an integrated operation analysis and comprehensive control platform for natural gas production with harmonized standards, unique collection source points and unified data processing rules.

Through the construction of Amu Darya Digital Gas Field, it can meet the integration and sharing application of various business data, and realize the tracking management and effective analysis of the whole process of natural gas production & operation from the formulation, execution, tracking, evaluation to optimization of production plans. By making a multi-dimensional display of the key indexes of production from a global perspective, it was able to solve the problems of poor sharing of production dynamic data, weak response ability of resource operation scheduling and insufficient auxiliary decision-making ability. Moreover, integrated management of production & operation can be achieved, and the requirements for production & operation management, production dynamic information data sharing and analysis, and effective production collaboration can be met, providing scientific basis for management and decision-making level to direct production and operation.

Company Introduction

Hongyou Software Co.is a local enterprise in software and information service industry in Xinjiang. It has R&D centers in Urumqi, Karamay, Beijing, Xi'an, Chengdu, Shenzhen and other cities in China. Its main business involves planning and design, product development, project implementation, system integration, and system operation and maintenance in the field of intelligent oilfields and smart cities. The smart oilfield market covers domestic enterprises such as CNPC, CNOOC, Sinopec, and Yanchang Group, and foreign oil and gas fields such as Amu Darya and Aktobe. Smart City City covers autonomous region government departments, Urumqi, Changji, Aksu, Altay, Hami, and other local cities and towns.

报名链接:

https://www.scobdc.org.cn/news/720071589999398922.html

- 关注我们

-

- 联系我们

- 中国信通院云大所 数据中心团队